|

Anping County Huijin Wire Mesh Co., Ltd.

|

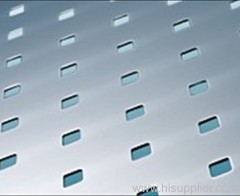

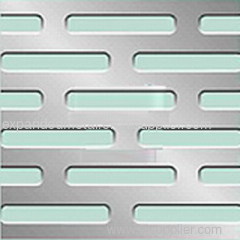

Slot hole perforated metal

| Price: | 0.5~500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Achieve high open areas with oval perforation from DBL.

We provide our customers with perforated metal sheets following specifications below:

Material

We can provide the following materials for perforating:

Stainless Steel, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals.

Specification

We can manufacture a wide rang of metal sheets with thickness verifying from 0.35mm to 5 mm and width maximum 1200mm. Length is the overall measurement of the long side of the sheet. Width is the overall measurement of the -short side of the sheet. The standard sheet size is 1000mm*2000mm. and 1000mm*2500mm. The coil width 1000mm is also available. We also can process the special product for your requirement.

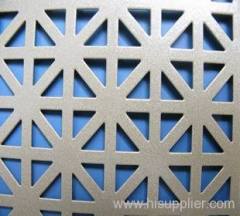

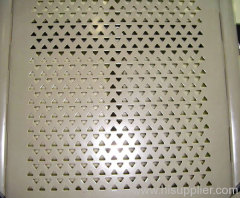

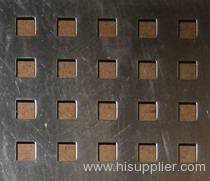

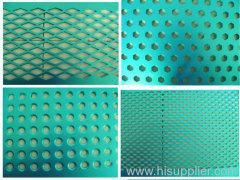

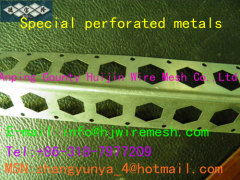

The hole shape for perforated metal products:

Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc.

Sheet Metal Aperture

In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved. The minimum diameter we can fabricate is 0.8mm to 4 mm thickness . If you require a die that isn't already in our die bank, our experienced tool and die makers can quickly make exactly what you need at a reasonable cost.

We can provide the following materials for perforating:

Stainless Steel, Galvanized Steel, Carbon Steel, Aluminum, and all types of metals.

Specification

We can manufacture a wide rang of metal sheets with thickness verifying from 0.35mm to 5 mm and width maximum 1200mm. Length is the overall measurement of the long side of the sheet. Width is the overall measurement of the -short side of the sheet. The standard sheet size is 1000mm*2000mm. and 1000mm*2500mm. The coil width 1000mm is also available. We also can process the special product for your requirement.

The hole shape for perforated metal products:

Round, square, long round, triangle, scale, diamond, oval, hexangular, slot etc.

Sheet Metal Aperture

In general it is advisable to use a hole size larger than the material thickness. The closer the hole size and material thickness come to a 1 to 1 ratio, the more difficult and expensive the process is. Dependent on the material type, smaller hole size to material ratios can be achieved. The minimum diameter we can fabricate is 0.8mm to 4 mm thickness . If you require a die that isn't already in our die bank, our experienced tool and die makers can quickly make exactly what you need at a reasonable cost.

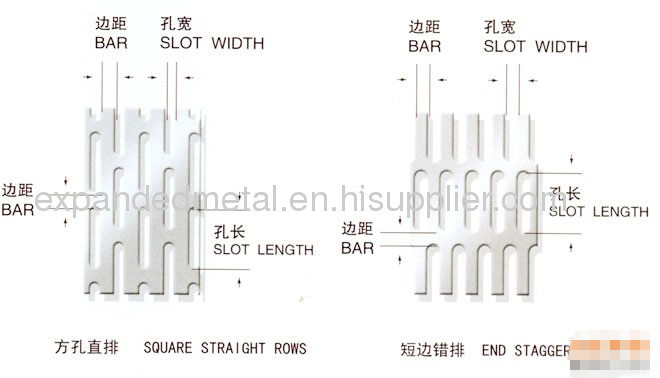

Pattern

We offer perforated sheets with more options and less cost. Equipped with computerized-programmable feed systems, we will expand your custom design options.

Our Perforated Sheet is available in the following patterns:

Round, square, oblong, triangle, slot, hex, oval, diamond and a broad variety of special shaped holes. We have tooling available for many different hole patterns and shapes. It is more economical to choose one of the available patterns, although special hole sizes and patterns can be accommodated at additional cost.

Pitch

Hole center is the distance from the center of one hole to the center of the nearest hole in the next adjoining row.

Open area

Open area is the total area of the holes divided by the total area of the sheet and is expressed as a percent , Keep in mind that punching holes in a material add stresses that can result in distortion of the product. The higher the open area, the more material distortion takes place, especially when the perforated pattern is bordered by margins on all four sides. But these distortions can be removed by our special in house leveling process.

Margins

Margins are the blank area along the edges of the sheet. If you want the product with special margins, you should provide the width of each margin on all four sides (measured from the edge of the sheet to the edge of the first hole).Manufacturing considerations may affect margins. If the margins requested are not possible. We will replace it with the similar products as your consideration.

Tolerances

There are tolerances on thickness, pitch, openings, flatness, and shearing for perforated products. You should specify a specific tolerance ,so we can give you a precise product. If not, we will according to standard tolerance.

Quality and Control: We utilize first-class software to plan, schedule, track and report each job that flows through our plant. It manages the life-cycle of quality control and continuous improvement events.

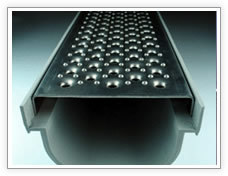

Capabilities: We can supply you with various perforated sheets as well as finished perforated metal products such as filter tubes, security screen, etc. We are committed to producing the highest quality parts on time and at a competitive price. We have over 10 years of manufacture experience Our products consist of perforated metal sheets, perforated screen, perforated panels, tubes, architectural mesh, expanded metal, perforated metal and expanded metal machines.

We offer perforated sheets with more options and less cost. Equipped with computerized-programmable feed systems, we will expand your custom design options.

Our Perforated Sheet is available in the following patterns:

Round, square, oblong, triangle, slot, hex, oval, diamond and a broad variety of special shaped holes. We have tooling available for many different hole patterns and shapes. It is more economical to choose one of the available patterns, although special hole sizes and patterns can be accommodated at additional cost.

Pitch

Hole center is the distance from the center of one hole to the center of the nearest hole in the next adjoining row.

Open area

Open area is the total area of the holes divided by the total area of the sheet and is expressed as a percent , Keep in mind that punching holes in a material add stresses that can result in distortion of the product. The higher the open area, the more material distortion takes place, especially when the perforated pattern is bordered by margins on all four sides. But these distortions can be removed by our special in house leveling process.

Margins

Margins are the blank area along the edges of the sheet. If you want the product with special margins, you should provide the width of each margin on all four sides (measured from the edge of the sheet to the edge of the first hole).Manufacturing considerations may affect margins. If the margins requested are not possible. We will replace it with the similar products as your consideration.

Tolerances

There are tolerances on thickness, pitch, openings, flatness, and shearing for perforated products. You should specify a specific tolerance ,so we can give you a precise product. If not, we will according to standard tolerance.

Quality and Control: We utilize first-class software to plan, schedule, track and report each job that flows through our plant. It manages the life-cycle of quality control and continuous improvement events.

Capabilities: We can supply you with various perforated sheets as well as finished perforated metal products such as filter tubes, security screen, etc. We are committed to producing the highest quality parts on time and at a competitive price. We have over 10 years of manufacture experience Our products consist of perforated metal sheets, perforated screen, perforated panels, tubes, architectural mesh, expanded metal, perforated metal and expanded metal machines.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Perforated Hole Mesh

Perforated Round Hole Mesh

Round Hole Perforated Sheet

Metal Hole

Hole Metal

Perforated Metal

More>>